PRODUCTION

50+ YRS EXPERIENCE IN WINDOW & DOOR MANUFACTURING

For over half a century, our window and door manufacturing process has been based on the highest quality work and artisanal craftsmanship. At the same time we never forget what drives us and has allowed us to stay at the forefront of an ever-changing market: our passion and innovation, coupled with our desire to fulfill extraordinary projects.

CUSTOM CREATIONS

Our production systems are developed and optimized specifically for each metal used in our custom creations. But we believe quality is about much more than the finished product. It’s about everything from the material to the small details, and our people who create with passion. For us, it is a way of life & our philosophy – a goal to instill emotions that clients can feel in our handmade products.

OUR PRODUCTION

The entire window and door manufacturing process is characterized by minimal automation and relies on the expertise of our highly skilled metal craftsmen with a long history of customizing products, projects and fulfilling dreams. Contact us for custom windows and doors.

PASSION AND INNOVATION ARE THE GUIDELINES OF OUR WORK

INITIAL STORAGE WAREHOUSE & QUALITY CONTROL

The first phase in window and door manufacturing includes warehouse storage of all materials needed to ensure smooth production. This area is divided into three main parts: receiving and inspection of goods area, semi-finished product area, and automated warehouse.

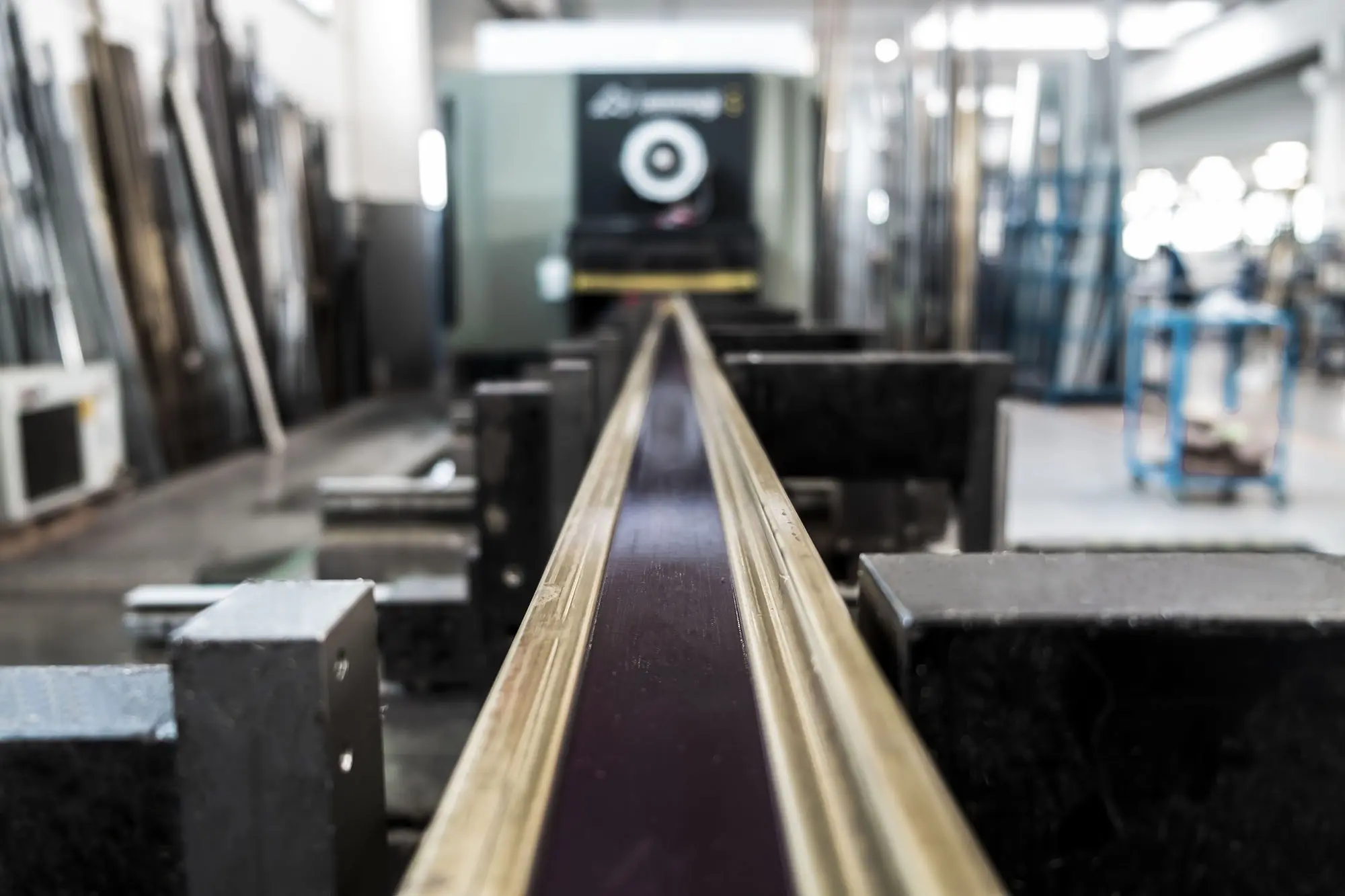

INCOMING RAW MATERIAL AREA

The initial & most important step after receiving materials is the strict inspection to ensure our internal quality standards. The long metal profiles are positioned on metal racks for quick pick-up, while the thousand small metal parts and details are managed by an automatic system allowing for coordinated filing. For Brombal, having this part of production work properly is vital in guaranteeing the highest quality product with on-schedule delivery.

PRECISION MAKES FOR PERFECTION

METAL CUTTING WORKSHOP

A word that better defines this phase – precision. The ultimate smart cutting machines used in the workshop allow us to cut the four metals we work with; all with details that make a difference. Beyond precision, these machines are unique in their ability to carry out different types of work at the same time keeping projects on schedule.

PRECISION AND ACCURACY

The 5-axis CNC machine is designed for milling, drilling, thread cutting, and cutting of bars or large pieces of steel and other metals. The high-power spindle with tool holder allows for heavy-duty performance with excellent results in speed and accuracy. As the first mechanical process in our metal window and door frame production, its outcome must be perfect to ensure precision in the following steps.

JOINING TRADITION WITH INNOVATION

PROFILE WELDING, VERIFICATION, AND PRE-ASSEMBLY

This stage contains several essential steps of the production process: welding of the profiles, mechanical finish, verification of measures, and hardware pre-assembly.

IT’S ALL IN THE DETAILS

The welding, completed by hand, allows for joining of different profiles to build the finished piece. Once raw construction of the window/door is ready and all parts are confirmed, the mechanical finish and the pre-assembly of metal hardware pieces is carried out to verify that final mounting is perfect. In the last phase all pieces are disassembled and sent to the paint shop, or burnishing in case of brass, along with the steel framework. In extremely unique designs, there is a special pre-assembly department that develops distinct works made by our most skilled Brombal craftsmen.

HIGH EFFICIENT PRODUCTION FOR HIGH EFFICIENT FENESTRATION

ROBOTIC PAINTING FOR MORE CONTROL

Painting is an essential process for achieving long-lasting protection and a perfect aesthetic on the surface. With the world’s most groundbreaking 6-axis robotic spray coating plant, our standards of painting steel windows and doors have reached the highest possible level in terms of precision, speed, and quality control.

CLEANING AND PROTECTION OF THE SURFACES

The liquid spray plant is composed of 2 robotic arms able to perform all the phases required for high quality painting. The first step is the cleaning of the metal piece; the first robot cleans and protects the metal. It has the ability to perform two functions that prepare it for the painting phase and can sandblast and metallize. Sandblasting is carried out by creating a high-speed flow of abrasive materials that clean the surface of all impurities and make it smooth even in its roughest areas. In the metallization process, molten metal is sprayed at high speed onto the metal’s surface to protect it from corrosion.

PAINTING AND HEAT TREATMENT

The second robotic arm has the power and aim to perfectly paint all parts of the metal, thanks to a 3D scanner that allows it to have complete control over the entire surface it’s working on. The next phase is the drying process which keeps the freshly painted piece in an environment of stable temperature and humidity, allowing the color to dry homogeneously. The last step is polymerization with the painted piece placed into a temperature controlled oven, ventilated at a constant temperature providing strength and high resistance to the exterior film to protect and ensure the finish’s beauty over time.

ART THAT’S STATE-OF-THE-ART

BURNISH PLANT

At Brombal no details are left to chance. Burnishing metal to a specific patina requires a craftsman’s touch. This is why we have invested in a new state of the art burnishing plant. Our burnishing plant guarantees us the flexibility to offer unique living finishes that enhance the metal’s natural beauty.

FINISH AND PROTECTION

For Brombal, having our own burnish plant gives us a great advantage that adds value to our products and their quality. The burnishing treatment is a corrosion prevention technique that provides a long-lasting product; it’s vital for giving us complete control over this process to deliver the highest quality on the market. At the end of the process the metal results in a darker finish that’s durable and resistant to heat & abrasion.

USING ULTIMATE TECHNOLOGY TO DELIVER HIGHEST QUALITY

FINISHING AND ASSEMBLY

The last step of the production process is finishing and assembly with Bombal’s craftsmen putting the final touches. Their notable expertise earned through years of experience and their passion for creation completes production. Each unit is handmade making every piece unique and a one-of-a-kind masterpiece.

FINAL ASSEMBLY & PACKAGING FOR SAFE DELIVERY

After receiving the material from the paint shop or burnishing plant, every single corner is inspected and refined by experienced hands to eliminate the slightest imperfection. Next all the hardware pieces, hinges, and gaskets are carefully mounted on the windows and doors. Once the units are ready, they are fixed on wooden studs and putting inside special crates with barrier bags and hygroscopic salts to prevent humidity.