Finishes

COLORS, FINISHES, AND TEXTURES

At Brombal, we allow the client to choose from a vast array of color palettes. Combined with state of the art application technology, we extend the Italian tradition of lasting quality for your fenestration masterpiece.

Based on location, Standard Painting or C5M Painting is available for projects in coastal environments.

Contact us to discuss your steel window and door / brass window and door project.

THE BURNISHING PROCESS

The prestige of brass comes from its look and high resistance to corrosion making it the ideal material for exquisite architecture. The special alloy used has properties which provide greater strength and a slight difference in patina is noticeable in corners which further highlights the handcrafted authenticity of Brombal’s artisanship.

THE PAINTING PROCESS

At Brombal, our finishing process not only helps to express the style of each project, but it protects the metal as needed. This is why our painting is so crucial allowing for maximum durability. Brombal’s new painting plant represents our company’s philosophy of freedom to create and quest for perfection.

FULLY AUTOMATED BURNISHING PLANT

BURNISHING

Brombal uses OT67 Brass alloy in which a high percentage of copper (67%) determines its high resistance to corrosion, while the remaining percentage of zinc (33%) improves its mechanical properties such as hardness and tensile strength.

A characteristic feature of this alloy is to naturally oxidize when in contact with air while maintaining its physical features; in turn obtaining that particular antique bronze finish that makes it ideal for prestigious refurbishments of historical buildings and for new high-end buildings - with a look that joins elegance and tradition.

Brombal offers 2 choices of finishes: Light Burnished Brass and Dark Burnished Brass.

Custom Burnish Options are available upon request.

STAINLESS STEEL

DISCOVER OUR STEEL OPTIONS

STAINLESS STEEL

The inalterability of the surface through the years, given by the production process, makes stainless steel the ideal solution for severe environments. The billet used for this metal is produced by forging the steel to the required gauge, then rolling it into large coils. The material then undergoes a finishing process to obtain a scotch-brite or polished surface. The coil is then rolled into the desired shape while a protective film is applied to protect the finish.

Scotch-Brite stainless steel: AISI 316L , 1,200 grit abrasives are rubbed over the surface to obtain a sleek smooth finish.

Polished stainless steel: AISI 316L , high powered buffers are used to create a polish like finish.

Textured Blackened Stainless Steel: the profile is glass blasted then dipped in an acid treatment to create a dark effect.

THE TIMLESS LIVING MATERIAL

CORTEN STEEL

CorTen steel has a unique and distinctive appearance. The intense richness of its finish bestows a warm, natural, yet at the same time extremely elegant look. Its attractive appearance is a result of an oxidation process which forms a protective coating. Upon exposure to air, the patina process begins which creates a protective layer of rust over the surface.

Left untreated, the rust will create an ever-changing appearance. A surface wax treatment can be applied which will provide a temporary protective barrier against the elements on the surface.

GALVANIZED STEEL

INFINITE COLOR SOLUTIONS

LIQUID PAINTING

Liquid spray painting is a technique in which a robotic arm sprays a coating (paint, ink, varnish) through the air onto the metal surface using spray guns. This process takes place inside a pressure-controlled room which uses large filters to create a dust/particle free environment for a perfect finish. The frames are then heated to dry and harden the paint as well as provide a smooth, consistent factory finish.

DISTINCTIVE METALS COLLECTION

The Distinctive Metals Collection are a premium finish which are more complex than standard liquid paintings. Unlike a normal liquid painting with uniform color and a smooth surface, our custom finishes have varied shades of color, a textured surface, and aesthetic effects that can imitate other materials such as copper, bronze, iron, concrete, etc.

Each special finish is the result of a long-studied process that results in the unique painted finish. Distinctive Metals Collection are available both Standard or C5M for badly polluted areas and/or coastal environments.

STANDARD PAINTINGS

Thickness: from 220 to 280 μm (micrometer).

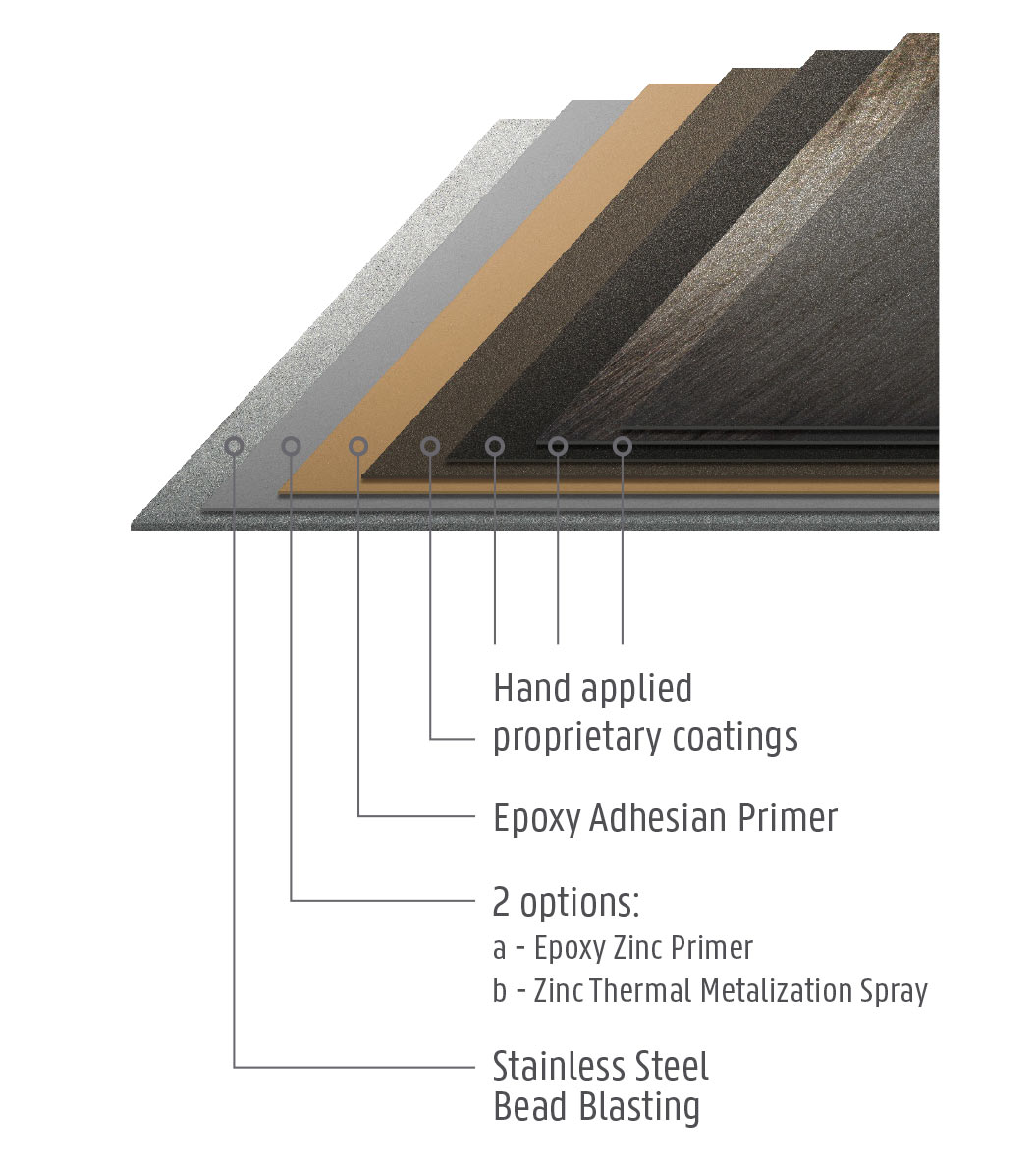

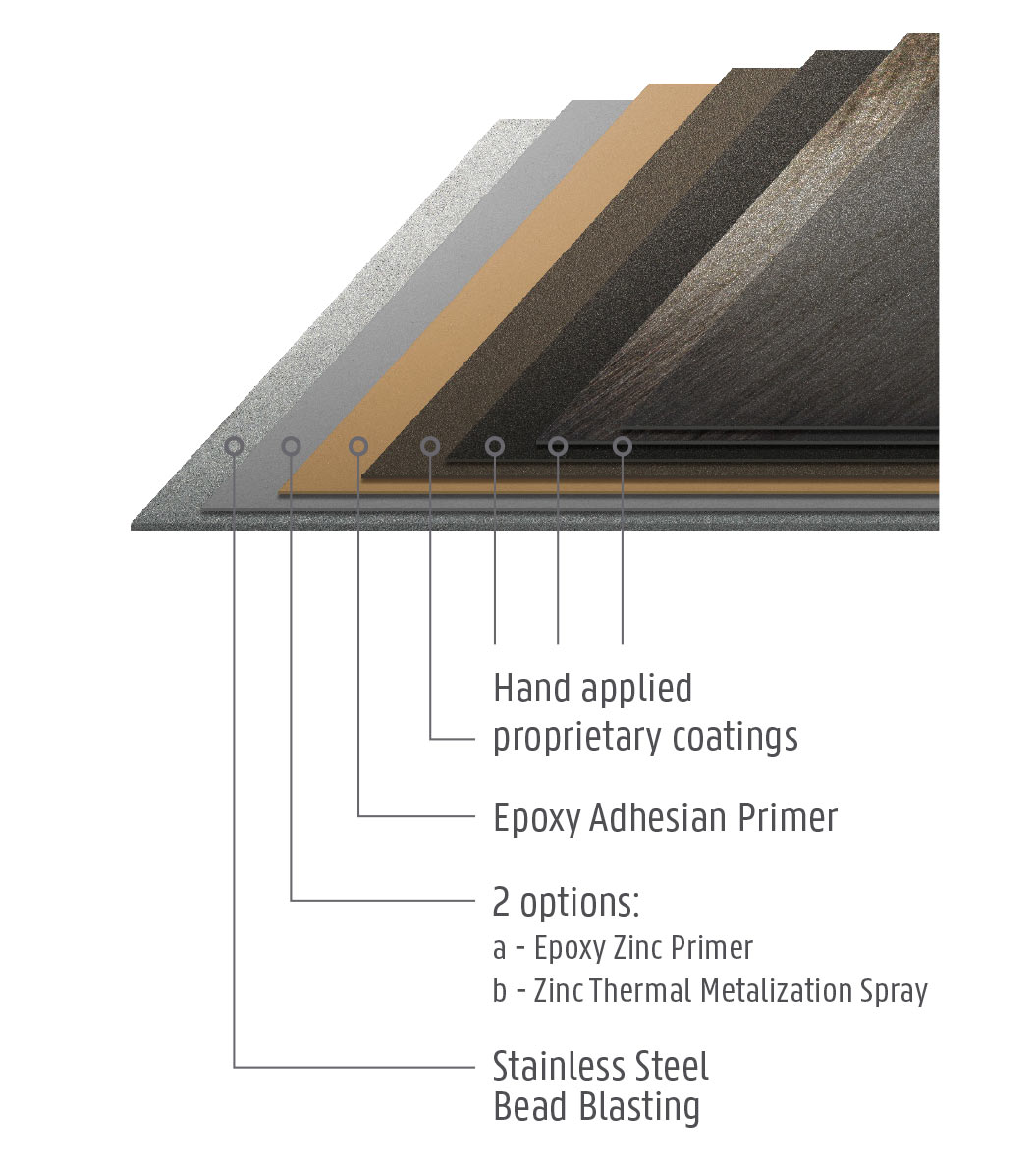

All the RAL & Texture Standard painting processes have four initial steps which guarantee very high adhesion between the base metal and the paint.

PAINT PROCESS:

1. Blasting all profile surfaces with micro stainless steel beads

(or other accessories that require painting).

Results of process:

– Surface becomes rough, allowing primer and paint to grip better to the steel;

– Cleaning dirt and contaminants from the steel surface.

2. Application of zinc basecoat:

a – Zinc Epoxy Primer, or;

b – Zinc Thermal Metalization Spray

Results of process:

– Prevents rust and corrosion.

3. Application of Epoxy Adhesion Primer.

Results of process:

– Seals the zinc coating;

– Prepares the surface making a strong bond for the finish coat.

4.The frames and accessories are then painted which vary between

finishes in coating thickness.

Results of process:

– Durable long-lasting protective coatings;

– Flexibility in color choice with smooth or textured surface.

Note: Stainless Steel does not require zinc coating described in step 2.

COASTAL AND POLLUTION RESISTANT

Thickness: from 300 to 360 μm (micrometer).

All the C5M RAL & Texture paintings have four initial steps which guarantee a very high adhesion between the base metal and the paint providing a very high resistance against marine environment and/or very polluted areas.

PAINT PROCESS:

1. Blasting all profile surfaces with micro stainless steel beads

(or other accessories that require painting).

Results of process:

– Surface becomes rough, allowing primer and paint to grip better to the steel

– Cleaning dirt and contaminants from the steel surface

2. Application of zinc basecoat:

a – Zinc Epoxy Primer, or

b – Zinc Thermal Metalization Spray

Results of process:

– Prevents rust and corrosion.

3. Application of Epoxy Adhesion Primer.

Results of process:

– Seals the zinc coating;

– Prepares the surface making a strong bond for the finish coat.

4.The frames and accessories are then painted which vary between

finishes in coating thickness.

Results of process:

– Durable long-lasting protective coatings;

– Flexibility in color choice with smooth or textured surface.

Note: Stainless Steel does not require zinc coating described in step 2.

RAL & TEXTURE PAINTING

Brombal offers liquid RAL painting with hundreds of color options available. Depending on location, a Standard or Coastal Paint will be used for your custom Brombal windows and doors.

STANDARD PAINTINGS

Thickness: from 220 to 280 μm (micrometer).

All the RAL & Texture Standard painting processes have four initial steps which guarantee very high adhesion between the base metal and the paint.

PAINT PROCESS:

1. Blasting all profile surfaces with micro stainless steel beads

(or other accessories that require painting).

Results of process:

– Surface becomes rough, allowing primer and paint to grip better to the steel;

– Cleaning dirt and contaminants from the steel surface.

2. Application of zinc basecoat:

a – Zinc Epoxy Primer, or;

b – Zinc Thermal Metalization Spray

Results of process:

– Prevents rust and corrosion.

3. Application of Epoxy Adhesion Primer.

Results of process:

– Seals the zinc coating;

– Prepares the surface making a strong bond for the finish coat.

4.The frames and accessories are then painted which vary between

finishes in coating thickness.

Results of process:

– Durable long-lasting protective coatings;

– Flexibility in color choice with smooth or textured surface.

Note: Stainless Steel does not require zinc coating described in step 2.

COASTAL AND POLLUTION RESISTANT

Thickness: from 300 to 360 μm (micrometer).

All the C5M RAL & Texture paintings have four initial steps which guarantee a very high adhesion between the base metal and the paint providing a very high resistance against marine environment and/or very polluted areas.

PAINT PROCESS:

1. Blasting all profile surfaces with micro stainless steel beads

(or other accessories that require painting).

Results of process:

– Surface becomes rough, allowing primer and paint to grip better to the steel;

– Cleaning dirt and contaminants from the steel surface.

2. Application of zinc basecoat:

a – Zinc Epoxy Primer, or;

b – Zinc Thermal Metalization Spray

Results of process:

– Prevents rust and corrosion.

3. Application of Epoxy Adhesion Primer.

Results of process:

– Seals the zinc coating;

– Prepares the surface making a strong bond for the finish coat.

4.The frames and accessories are then painted which vary between

finishes in coating thickness.

Results of process:

– Durable long-lasting protective coatings;

– Flexibility in color choice with smooth or textured surface.

Note: Stainless Steel does not require zinc coating described in step 2.