The Painting Test Laboratory

For Brombal, increasing the quality of its products means operating through three main elements: experience, product knowledge and constant Research & Development.

The discovery of new solutions for increasing performances, pushes the company to proactive and innovative choices, as happened with the implementation of the new analysis and test laboratory in the painting department.

This new technological instrumentation introduces a series of tests to analyze the reactions developing on painted products

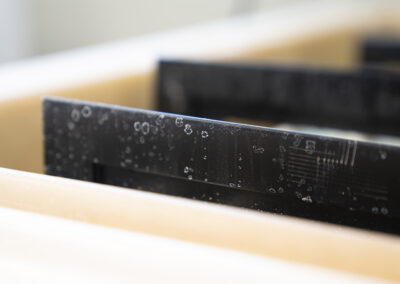

The system consists of a pump, a tank with salted water and the computerized test chamber which allow the laboratory technician to verify each effect found on the exposure, in certain contests, of Brombal products; particular environmental conditions are, in fact, recreated by the machine through a series of processes with marked saline and humidity values, all specifically designed.

Different duration, intensity and temperatures constitute the characteristics of the test cycles, where the salt fog is vaporized according to the programming of these values.

In the first phase the sample product to be tested is checked for its integrity, thickness of the paint, the gloss and, with a spectrograph analysis, the colour.

In some cases the laboratory technician will engrave the layer of the paint with a ‘paint cutter’, a special tool with an ‘adhesion test ‘ method, which will create an incision in the paint consisting of 49 small squares with dimensions of 1x1mm.

This operation will be used in the test phase to check the delamination of the paint.

The sample is then codified and positioned inside the machinery test chamber: here it will undergo various technical stresses due to the different programmed cycles.

The monitoring to verify the reactions are planned in steps of 1,000; 1,500; 2,000 hours and more, at each check all the values considered in the first analysis will be re-examinated, the comparison and the evaluations drawn from the observations will lead the R&D department to the study of new solutions.

The results of the tests carried out show that all Brombal products reach high test standards without the presence of any blistering (trapping of water under the paint layer) and, in the case of adhesion test, the verification of potential delamination of the paint.

Among these checks, the Distinctive Metal Collection stands out in a particular way, this precious collection of Brombal finishes responds to the most demanding tests with the highest results among all the paints tested.

The Painting Test Laboratory, another piece of innovation that Brombal adds, day after day to the quality of its exclusive luxury windows & doors frames.